BG90-101 Braking device module

| Name of the assembly group: | BG90-101 |

|---|---|

| Use function: | The BG90 replaces the brake contactors required by EN81, as well as an electronic brake control for overexcitation of the brake coils. |

| Time of use: | From 2013-07 |

| Dimensions (with shell): | (length x width x height) 150 mm x 70 mm x 183 mm |

| Weight: | Approx. 1500 gram |

| Power supply: | +24V DC / 230V AC / 205V DC |

| Switching cycles: | Approx. 1,000,000 switching cycles |

| Protection level: | IP 43 / pollution degree II |

| Place of installation: | In the control cabinet |

| Ambient temperature: | 0 to +45 °C |

| KW-Number: | 1100225 |

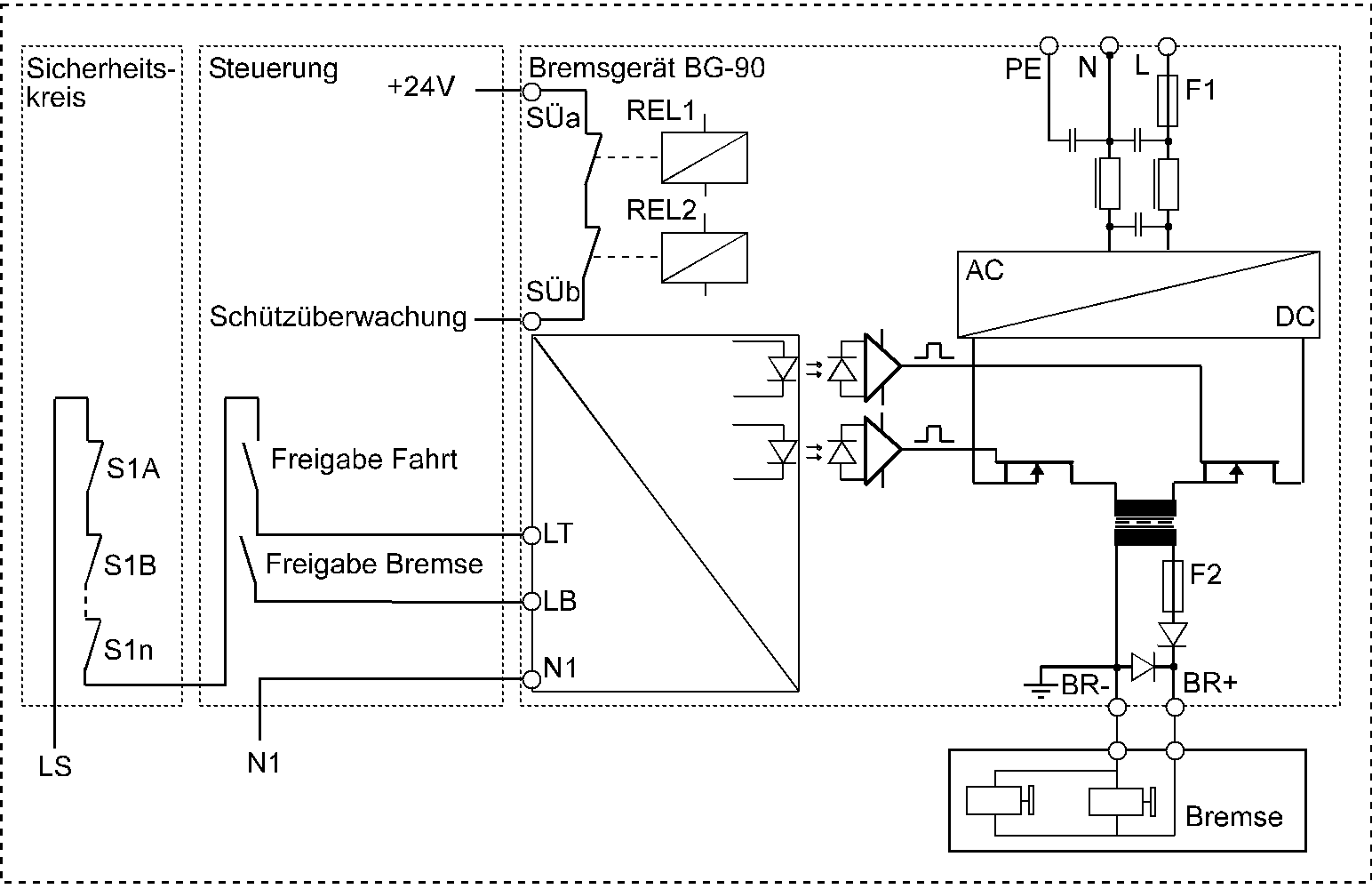

ROPE - BG90-101 Braking device assembly - Functional description

The BG90 replaces the brake contactors required by EN81, as well as an electronic brake control for overexcitation of the brake coils.

of the brake coils. The BG90 can be used to control brake solenoids for elevator drives with rated currents of up to 2.5A.

This means that no brake contactors or additional electronic brake control are required when using the BG90.

is required. The brake coils are controlled purely electronically without contactors, the output voltage is switched off after an adjustable time (0.5.

adjustable time (0.5..3 seconds) from 200VDC to 50..150V (adjustable).

To control the brake coil, the two enable inputs must be supplied with 230VAC from the safety circuit.

The mains voltage (230VAC)= is always present. If the safety circuit is interrupted and therefore the enable inputs cannot receive any

control voltage, the brake coil is safely disconnected from the mains voltage. This is achieved by an

intrinsically safe electronic circuit (functional safety) without additional contactors.